Heat Reflective Paint | 5 Application Steps, Benefits & Selection

Heat reflective paint is regular paint with a heat reflective quality. It improves buildings’ insulation properties in an eco-friendly way, and these paints are generally available in light colors because up to 80% of solar radiation can be reflected by these.

By adding tiny spheres or flakes of material like glass, glitter, or another additive such as crystal that paint a reflective quality, reflectivity in paint is made.

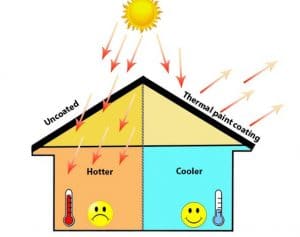

Heat reflective paint has been designed to reflect more sunlight and absorb less heat, and its application reduces roof temperature and correspondingly reduces the room’s temperature. The power consumption is reduced due to the lowered temperature gradient across the slab in air-conditioned spaces.

By emissivity aqueous coating based on acrylic- resins, heat reflective paint is made of a highly reflective type of paint and eco-friendly.

Application of Heat Reflective Paint:

There are the following steps in the application of heat reflective paint as given below:

- With water or bleaching powder, cleaned ores should be washed and before each use, stir the paint thoroughly.

- Then on the cleaned and washed surface, apply the first coat with a brush.

- Then after a gap of a minimum of 3 to 4 hours, apply the second coat.

- For at least 2 hours, ensure that the coated area does not come in contact with water.

- It should be allowed to cure after completion of the full coating.

By spraying, roller, or brush, it can be applied and is easy to apply and can replace bulky conventional and standard insulation materials.

Benefits of Heat Reflective Paint:

There are the following benefits of heat reflective paint as given below;

- This paint Continuous rejection of solar heat resulting in the drastic reduction of roof heat like ultraviolet and infrared rays and reflects these rays back to the atmosphere.

- For the false ceiling, it eliminates the necessity.

- On any roofing material or sidewalls, this paint can be coated.

- This paint helps in reducing global warming and the emission of greenhouse gasses.

- Cool roof surfaces can be more susceptible to algae in warm and moist locations.

- It can be cleaned up with water because it contains no solvents.

- No toxic substance is included in this paint.

Selection of Heat Reflective Paint:

- The excellent heat-reflective paint has a Solar Reflectance Index (SRI) value of 121 to 123.

- Volatile organic compounds for this paint should be between 1.2- 1.34gm per liter.

- It should have zero toxic substances and not have any type of solvents.

- This paint should be waterproof, dustproof, and also during monsoon resistance to fungus.

Best Heat Reflective Paint: (Excel CoolCoat)

Excel excellent coat has the highest solar reflective index value of 122 that ensures high reflectivity and a sound reduction in temperature and is a solar reflective paint.

This paint is lab-tested and proven to repel heat, and the application procedure is effortless, and any ordinary painter can do it.

Features of Excel CoolCoat:

There are the following features of this paint such as;

- This paint serves the summer cooling purpose and can be used as the best heat reflective paint for exterior walls.

- When this type of paint is coated on the roofing materials, then this paint prevents the roofing materials from getting heated up even in peak summer afternoons and reflects sunlight to a greater extent.

- The air below the roof never gets hot and keeping the rooms cool and comfortable because it works on the principle of continuous rejection of ultraviolet and infrared rays.

- To efficiently protect heat from entering inside, EXCEL CoolCoat contains high-performance Nano-insulating material.

- For plastic and other surfaces such as cement, RCC roof, tiles, aluminum, and other materials, this paint acts as the best heat reflective paint.