flexible pavement

Flexible pavement is constructed from the stress that is transmitted to the sub-grade through the lateral distribution of the applied load with depth and unbound or bituminous material.

This layer is composed of a surface course and bituminous material underlying base. The bituminous material is more often asphalt material whose viscous nature form allows significant plastic deformation.

Most asphalt surfaces are built on a gravel (aggregate) base, although sometimes the full depth of the asphalt surfaces are built directly layer on the subgrade. Depending on the temperature at which it is applied asphalt on the road, asphalt is categorized as hot mix asphalt (HMA) cold mix asphalt, warm mix asphalt.

They are so named as the pavement surface reflects the total deflection of all subsequent layers due to the vehicle load acting upon it. Their design is based on the load-distributing characteristics of a layered system.

It transmits the load to the combination of layers through a subgrade. Flexible pavement distributes the load over a subgrade beneath a relatively smaller area. The initial installation of a flexible pavement cost is quite low which is why flexible pavement is more commonly seen universally.

However, flexible pavement requires routine and maintenance repairs every few years. In addition, flexible pavement defects rapidly; potholes and cracks are likely to appear due to heavy vehicular traffic and poor drainage.

Stress Distribution in Flexible Pavement

A valuable advantage of flexible pavement can be opened for traffic within 24 hrs after the completion of the road. Also, the maintenance and repair of flexible pavement are cost-effective and easy.

Today 96% of all streets and paved roads in Pakistan are surfaced with asphalt. Almost all paving asphalt layers used today are obtained by processing with crude oils. Man-made asphalt consists of compounds of carbon and hydrogen with minor proportions of nitrogen, oxygen, and sulfur.

Types of Flexible Pavements

- Conventional layered flexible pavement

- Full-depth asphalt pavement

- Contained rock asphalt mat (CRAM).

Conventional layered flexible pavements;

They are layered systems with high-quality expensive materials are placed in the top where stresses are low and high-quality cheap materials are placed in lower layers.

Full-depth asphalt pavements;

They are constructed by placing directly on the soil subgrade of bituminous layers. This is more suitable when there are local materials and high traffic is not available.

Contained rock asphalt mats (CRAM):

They are constructed by placing open or dense graded aggregate layers in between two asphalt layers. Modified dense graded asphalt concrete placed above the subgrade will significantly reduce protection from surface water and the vertical compressive strain on soil subgrade.

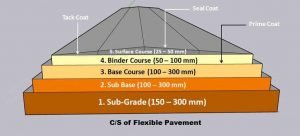

Typical layers of a flexible pavement

Typical layers of a conventional flexible pavement include tack coat, prime coat, base course, sub-base course, seal coat, surface course, compacted subgrade, binder course, and natural subgrade.

Seal Coat:

This is a thin surface treatment to provide skid resistance and used to water-proof the surface.

Tack Coat:

This is a very light application of asphalt, usually, asphalt emulsion meets with water. Tack coat provides proper bonding between two layers of must be thin and binder course, set very fast, and uniformly covering the entire surface.

Prime Coat:

It is low viscous cutback bitumen to an absorbent surface like granular bases on which the binder layer is placed on the road layer. The prime coat provides bonding between two layers together. Unlike tack forms and coats a watertight surface.

Surface course:

This layer directly in contact with generally contains superior quality materials and traffic loads. Surface layers are usually constructed with dense graded asphalt concrete. The requirements and functions of this layer are:

The surface course provides characteristics such as smoothness, drainage, and friction, etc. Also, the surface course will prevent the entrance of excessive quantities of surface water into the sub-base and sub-grade, underlying base.

Surface courses must be tough to resist to provide a smooth and skid- resistant riding surface and distortion under traffic.

They must be waterproof to protect the entire subgrade and base from the weakening effect of water.

Binder course:

The Binder course layer provides the bulk of the asphalt concrete structure. The Binder course’s chief purpose is to distribute the load to the base course. The binder course generally consists of aggregates that don’t require quality as high as the surface course and less asphalt.

Base course:

It provides additional load distribution and contributes to the sub-surface drainage and This layer of material immediately beneath the surface of the binder course and It may be composed of crushed stone, other untreated or stabilized materials, crushed slag.

Sub-Base course:

The sub-base course layer of material beneath the primary functions is to provide structural support and base course, improve drainage, and reduce the intrusion of fines from the sub-grade in the pavement structure. If the base course is open-graded, then the base course A sub-base course is not always needed or used and the sub-base course with more fines can serve as a filler between subgrade.

Subgrade:

We are known for topsoil is a layer of the pavement of natural soil prepared to receive the stresses from the layers above. the subgrade is essential that at no time soil subgrade is overstressed. the subgrade should be compacted to the desired density and near the optimum moisture content.

The methods of design are broadly classified as:

- Analytical or mathematical methods.

- Mechanistic-empirical methods.

- Semi-empirical methods

- Empirical meth

We Love Cricket