Modulus of Resilience: Definition, Calculation & Examples

Modulus of Resilience

The modulus of resilience is the maximum amount of energy per unit volume that a material can absorb and still return to its original position.

By a material per unit volume, the maximum amount of energy that can be absorbed without creating any permanent deformation in the elastic limit is known as the modulus of resilience.

The idea of the modulus of resilience is a must for you if you want to be a good structural engineer and actually resilience means that the capabilities of a body to consume energy when in the elastic limit the body is deformed.

As ‘μ’ it is normally denoted and the limit is the elasticity limit and also some time donated as Ur. From material to material, the modulus of resilience varies because, for varying materials, the elasticity limit is not constant.

What is Resilience?

Resilience means that the capability of a body to consume energy, when in the elastic limit and they will withstand and come back to their original position from difficult conditions.

- Due to resilience property, without having permanent deformation a material can store energy, and as soon as the load is removed and the energy is released and due to this, there is no permanent deformation in the body.

- In material for spring action, this property is desired.

Calculation of Modulus of Resilience:

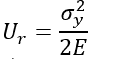

Let’s see the equation to calculate this modulus;

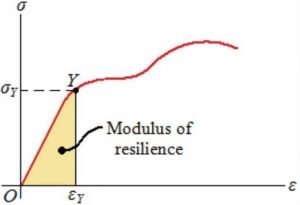

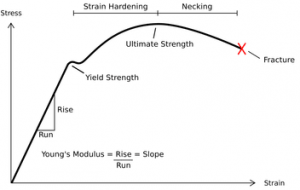

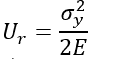

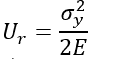

As we know resilience is an engineering term that refers to the amount of energy that a material can absorb and still return to its original position. So the area under the elastic portion of the stress-strain curve for that compound and the modulus of resilience as μ or Ur for a given compound is given as;

Where,

- Ur or μ is the modulus of resilience.

- σ1 is the yield strain.

- And E is young’s modulus

To find out this modulus from the stress-strain diagram, there is also a way;

There is a stress-strain diagram and the resilience of the material is the area under the linear portion of a stress-strain curve and you will find the modulus-of-resilience if you combine the stress-strain curve from zero to the elastic limit.

Unit of the Modulus of Resilience:

The unit of the modulus-of-resilience is nothing but the quantity of energy absorbed by per unit volume of a body and the unit will clearly be Joule per cubic meter (J.m-3) in the SI system.

By the stress-strain diagram, it is also provable as given below;

- The area underneath the stress-strain (σ–ε) curve up to yield = μ = σ × ε.

- μ = Pa × % = …. N·m−2.

- μ = …. N·m·m−3.

- μ = J·m−3.

So, the structural engineer or civil engineer always has to work with materials and in a passive way, the parameter modulus-of-resilience expresses the elasticity limit of a body. The load-bearing capability of a body is also symbolized.

Examples of Modulus of Resilience:

For each of the following material calculate the modulus-of-resilience:

Materials | Yield Strength | |

Mpa | Psi | |

Steel Alloy | 550 | 80,000 |

| Aluminum Alloy | 250 | 36,250 |

The equation for determining this modulus is

For Steel

= (550 x 10^6 N-m2)2 / (2)207 x 10^9 N /m2

= 7.31 x 10^5 J/m3

For Aluminum

= (250 x 10^6 N /m2)2 / (2) 97 x 10^9 N /m2

= 6.31 x 10^5 J/m3.